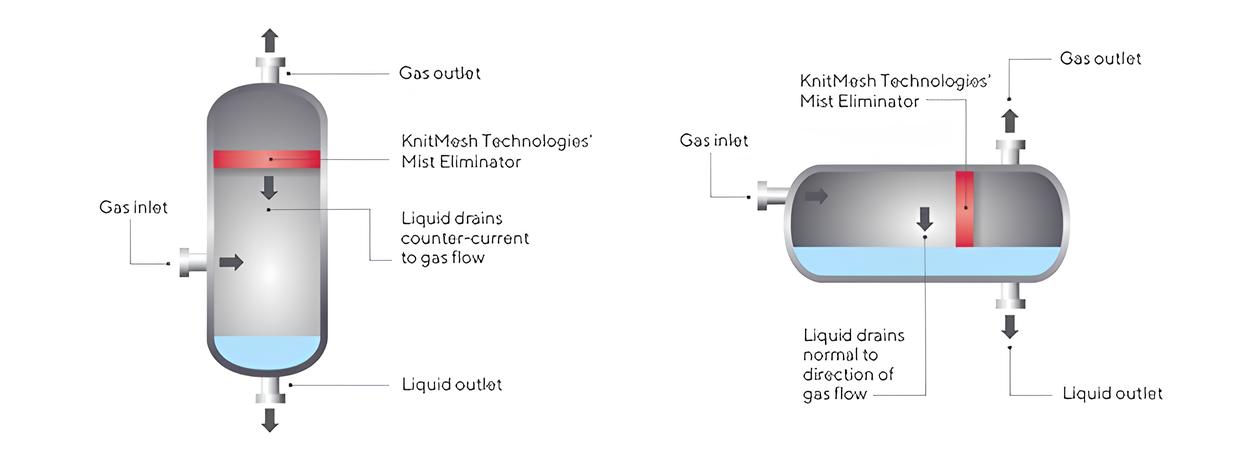

Demister Operating Principle

Demister systems are high-efficiency mist eliminators designed to mechanically separate liquid droplets carried within gas streams.

As the gas stream passes through the demister element, droplets are captured on the wire mesh’s large surface area, coalesce, and are removed from the system by gravity.

- The gas phase is directed to the outlet line with low pressure drop

- The liquid phase is drained through discharge points depending on the flow direction

Thanks to this structure, demisters provide a safe, long-lasting, low-maintenance solution for oil & gas, chemical, energy, water treatment and marine applications.

Style & Specifications

Demisters made from wire mesh are available in different diameters. Small diameters are typically supplied as a single piece, while large diameters are usually divided into sections for easier transport and installation. We can manufacture to the requested dimensions and sectioning.

| Style & Specifications | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Style | Density kg/m3 | Volume % | Surface Aream2/m3 | TCI | Equivalent | ||||

| York | Knit | Vico-Tex | Koç | Meteks | Note | ||||

| H | 80 | 99.0 | 158 | TCI-80 | 931 | 4536 | 160 | 511 | High |

| L | 120 | 98.5 | 210 | TCI-120 | 422 | ||||

| N | 144 | 98.2 | 280 | TCI-144 | 431 | 9030 | 280 | 911 | New Standard |

| SN | 128 | 98.4 | 460 | TCI-128 | 326 | 415 | 706 | ||

| SL | 193 | 97.5 | 375 | TCI-193 | 421 | 9033 | 380 | 1211 | Extra Dense |

| S.M. | 300 | 96.2 | 575 | TCI-300 | |||||

| ŞŞ | 390 | 95.0 | 750 | TCI-390 | |||||

| T | 220 | 97.2 | 905 | TCI-220 | |||||

| R | 432 | 94.5 | 1780 | TCI-432 | 333 | 800 | Multi-wire | ||

| B | 220 | 97.2 | 428 | TCI-220 | Yara | ||||

| GS | 160 | 96.7 | 5000 | TCI-160 | 371 | ||||

| - | 117 | 98.5 | 213 | TCI-117 | 483 | ||||

| - | 64.1 | 97.0 | 413 | TCI-64F | 221 | ||||

| - | 64.1 | 97.0 | 492 | TCI-64P | 241 | ||||